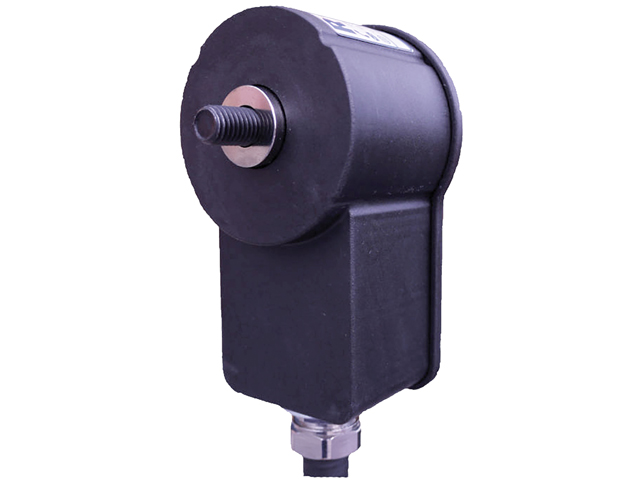

Shaft Encoders PPE4000 Series

The PPE 4000 series of Rotech shaft encoders are manufactured in an extremely tough and durable 30% glass fibre reinforced polypropylene housing.

A wide range of number of pulses per revolution are available together with AC and DC electrical outputs.

The SS 4000 Series of Rotech Speed Switches are a compact range of Duty shaft speed sensors with an internal speed relay adjustable over a typical range of 1 to 250 rpm.

A wide range of customer specialized options are available including relay or solid – state outputs, start delays and speed ranges from 0.01 rpm to 10 000 rpm.

Installation is simple and easy, just requiring one 12 mm tapped hole in the end of the shaft being monitored.

Products from the Rotech range

Products from the Rotech range

PVS 4000 Series

Vibration sensor for monitoring:

- Vibrating screens

- Slowdown

- Stoppage

- Breakage

- Irregular vibration

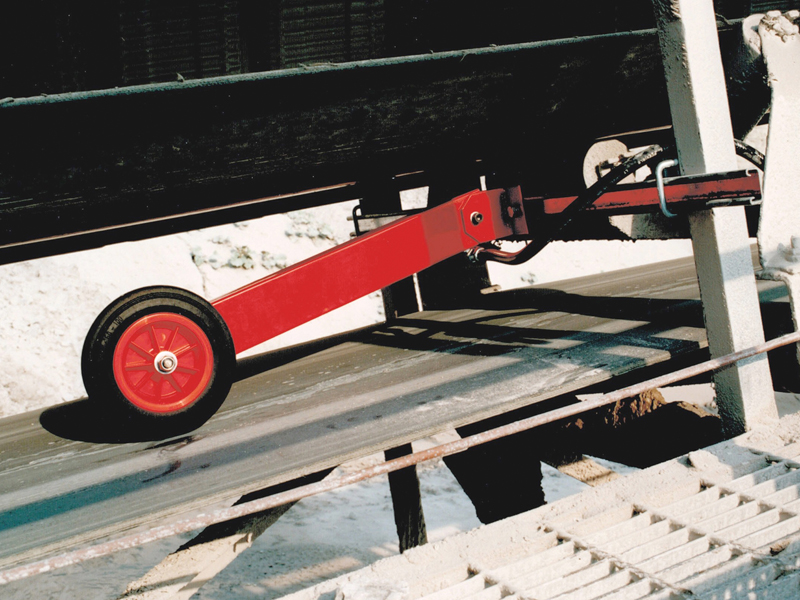

On a conveyor and elevator they should be installed on the tail drum, tail roller, snub roller, gravity take up roller or any roller that is driven by the conveyor belt itself.

Alternatively the Rotech Wheel Driven Motion Sensors can be fitted directly to run on the return side of the Conveyor Belt.

Any slowing down of the Drive Motor, Gearbox, Drive Chains, Drive Belts, or the conveyor belt slipping, etc, will result in the conveyor belt and the selected drum/roller slowing down which will be detected by the Motion Sensor.