DUNLOP COUPLINGS

DUNLOP flexible and rigid couplings form a vital link between mating components covering virtually any industrial application, from low power low speed general purpose drives, through to high power high torque applications. Flexible couplings cater for misalignment, absorb shock loads and damp out vibrations, while rigid couplings provide a convenient method of rigidly connecting the end of shafts.

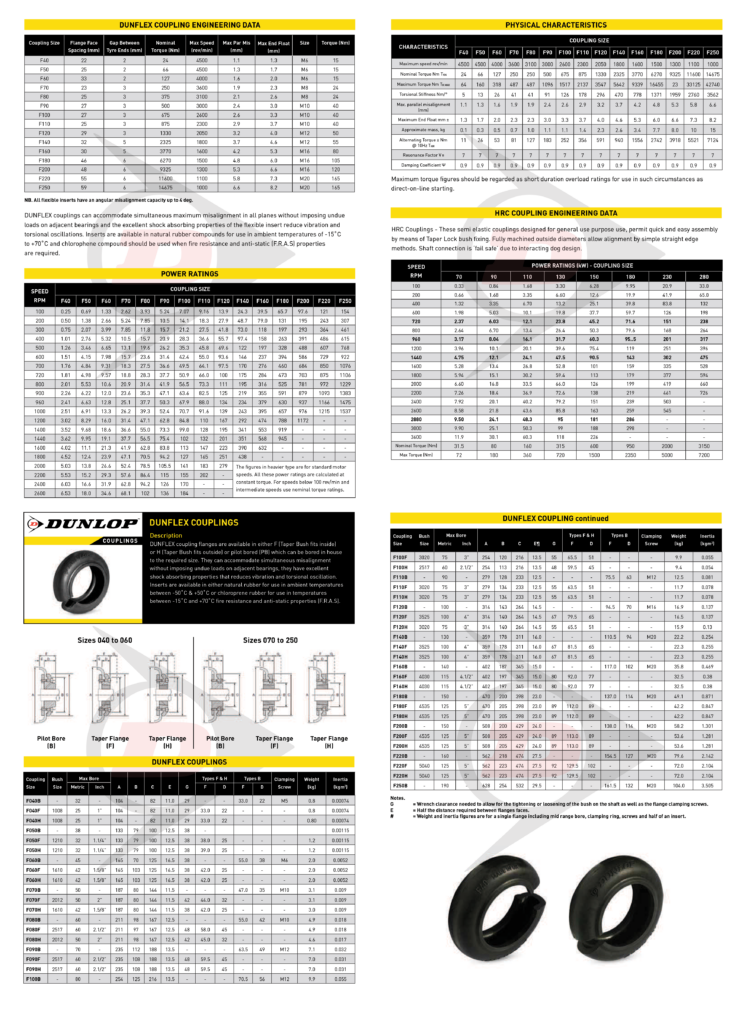

HRC Coupling

HRC coupling flanges are available in either F (Taper Bush fits inside) or H

(Taper Bush fits outside) or pilot bored (PB) which can be bored in house to the

required size. These semi-elastic couplings are designed for general purpose

use, they permit quick and easy assembly by means of taper bush fixing to the

mating shaft.

JAW Coupling

Jaw coupling flanges are available either pilot bored (PB) which can be bored

in house to the required shaft size they are also conveniently held in stock in all

popular metric and imperial bore sizes with corresponding key way and 2 grub

screws at 90’ to each other for securing to a shaft.

They suit general purpose applications that cater for misalignment, shock

loads and damp out small amplitude vibrations.

RIGID Coupling

Taper Bore Rigid Couplings provide a convenient method of rigidly

connecting ends of shafts. These couplings have a male and female flange fully

machined. The male flange can have the taper bush fitted from the Hub side (H)

or from the Flange side (F), the female flange

always has the bush fitting (F).

This gives two possible coupling assemblies (HF) and (FF). When

connecting horizontal shafts, the most convenient assembly should be chosen.

When connecting vertical shafts use assembly (FF) only.

TAPER BUSHES

Dunlop Taper Bushes are the most convenient and cost effective method of

fixing components to a mating shaft without using any special tools. Taper

Bushes are pre-machined with the required bore & keyway size and are

supplied complete with locking set screws, thus making savings in time and

cost on any machining process. They are available with both metric or imperial

bore and keyway size options.

Taper Bushes are designed for use with V-Pulleys, Chain Sprockets, Micro

V-Pulleys, Timing Belt Pulleys, Couplings, Weld-On & Bolt-On Hubs. Part

numbers are identified by a 4 digit number (e.g. 1610) which represents

the taper bush series followed by the bore size (e.g. 28mm) for example

1610x28mm.

WELD ON HUBS

Taper Bore Weld-on-Hubs are made out of steel, drilled, tapped and taper

bored to receive standard Taper Bushes. The extended flange provides

a convenient means of welding hubs into fan rotors, steel pulleys, plate

sprockets, impellers and other devices which must be firmly fastened to

the shaft.

Weld-on-Hubs are easy to install and entirely suitable for use where severe

operating conditions are met. Weld-on Hubs are manufactured to complement

the Taper Bush range. All are manufactured from C45 Steel.