PVS 4000 SERIES

Vibration Sensor

Comprising Product Code PVS -1-E3-HD

Heavy Duty – Aluminium Body

For Monitoring:

Vibrating screens

Slowdown

Stoppage

Breakage

Irregular vibration

From a pilot introduction starting in 2000, Rotech Systems now have thousands of PVS4000 Vibration Protection Systems

in operation.

Most modern screens are designed with the benefit of computer simulation and can therefore cope with a wide range

of operational conditions.

Variations in feed rates and composition of the material being fed to a screen (wet, sticky, etc.) can however in some

circumstances result in an excessive amount of material being on the screen.

If as a result, the rate and speed of vibration of the screen slows down, even temporarily, problems can occur very

quickly.

Material continues to be fed to the screen at the normal rate but the slowdown causes the discharge rate to be

reduced, a marginal overload can quickly enter a runaway situation with the material arriving at the screen causing

an every increasing overload and further slowdown, the discharge rate is then further reduced and the overload

increases exponentially.

Mechanical Failure – “V” Belt damage or the intervention of the screen drive motors electrical overload is

often the first thing the operator will know that all is not well!

Overloaded screens and feeders, V belt damage, spillage, cleaning up, etc. and their associated downtime and

lost production can now be a thing of the past.

Key elements in the design brief were:

- Quarry environment construction to ensure long term reliability, easy installation and simple setting up.

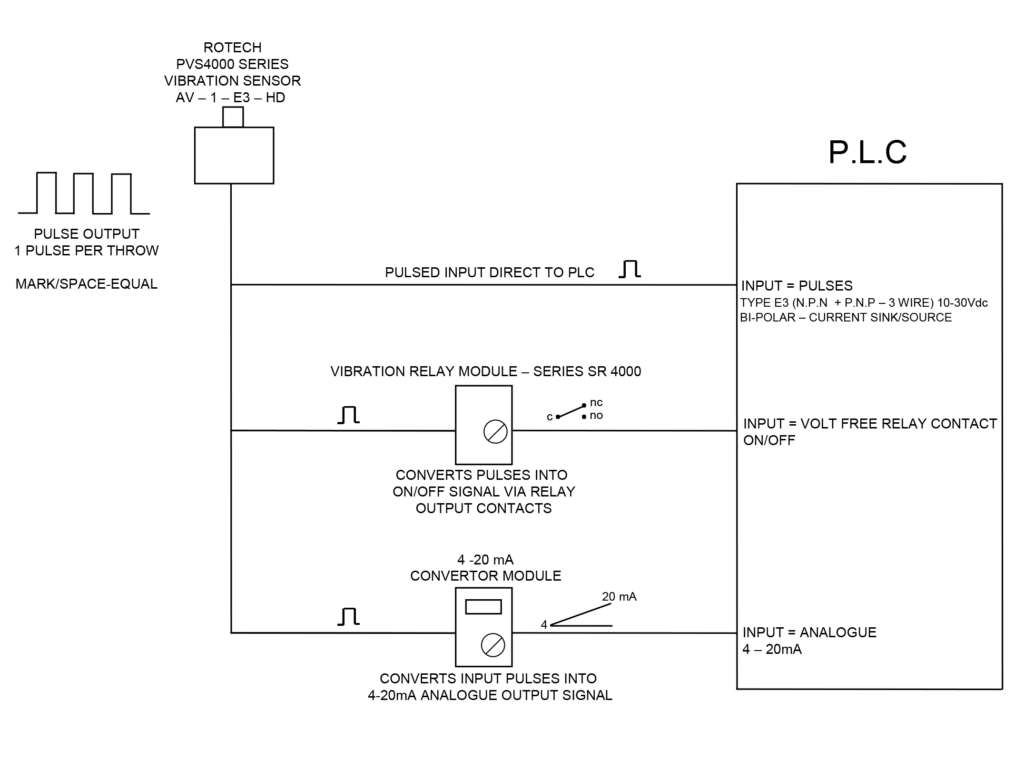

- A ‘Rotech’ vibration sensor, fitted to screen, monitors its rate of vibration and will operate an alarm or switch the in – feed conveyor off if the screen slows down.

- Accuracy is such that even a drop in speed of 5% for a few milliseconds can be detected and action taken almost instantaneously.

- On V–belt driven screens, the screen drive motor can be switched off the instant any slippage occurs, preventing costly damage to belts.

The PVS4000 Vibration sensor is housed in heavy duty aluminium housing with all internal components and cable

connections fully encapsulated.

It is supplied complete with a heavy duty galvanised angle bracket that is simply bolted or welded to the side of the

screen or feeder. A heavy liquid tight flexible conduit is then looped to a convenient electrical junction box and the

signal

routed by standard PVCSWA cable back to the main control panel.

The associated PSR4000 Speed Relay Control Module has a single dial that is turned to locate the actual running

speed of the screen / feeder and then set to just below this speed.

Typically on a screen / feeder vibrating at 750 throws per minute the speed relay is set to 725, if the speed drops

below this level the PSR4000 speed relay operates in less than 10 millisecond.